Benefits Of Stainless Steel Pickling In The Power Generation Industry

by Neil Brook on March 4, 2025

Stainless steel pickling is an important maintenance process for equipment and components used in the power generation sector, improving the reliability and durability of assets exposed to demanding conditions, and maintaining compliance with industry standards. The pickling process r …

Rouge Types: What Are The Three Main Classes Of Rouge?

by Neil Brook on January 21, 2025

Stainless steel tubes and applications can sometimes develop rust-coloured surface corrosion, or rouge, under certain conditions. Removing this corrosion – or derouging stainless steel– is crucial for preventing damage to your systems and equipment and maintaining product safety, as u …

Understanding The Need For Pre-Commission Cleaning Of Pipework Systems

by Neil Brook on November 26, 2024

Pre-commission cleaning is an essential part of implementing any new pipework system, ensuring long-term performance and quality, as well as compliance with hygiene and safety standards.

Importance Of Equipment Cleaning Validation In Pharmaceutical Industry

by Neil Brook on November 5, 2024

Equipment cleaning validation is a documented process or audit trail conducted by specialised engineers, it explains the procedures required and actions taken to effectively remove microbial or chemical residues from manufacturing equipment. In the pharmaceutical industry, this valida …

The Importance Of Riboflavin Testing For Equipment Safety

by Neil Brook on October 22, 2024

Riboflavin testing is a quality assurance method for evaluating the effectiveness of vessel tank cleaning processes and is a mainstay in the pharmaceutical manufacturing sector, food processing, and other sanitary settings. Riboflavin testing is also used as a preliminary for passivat …

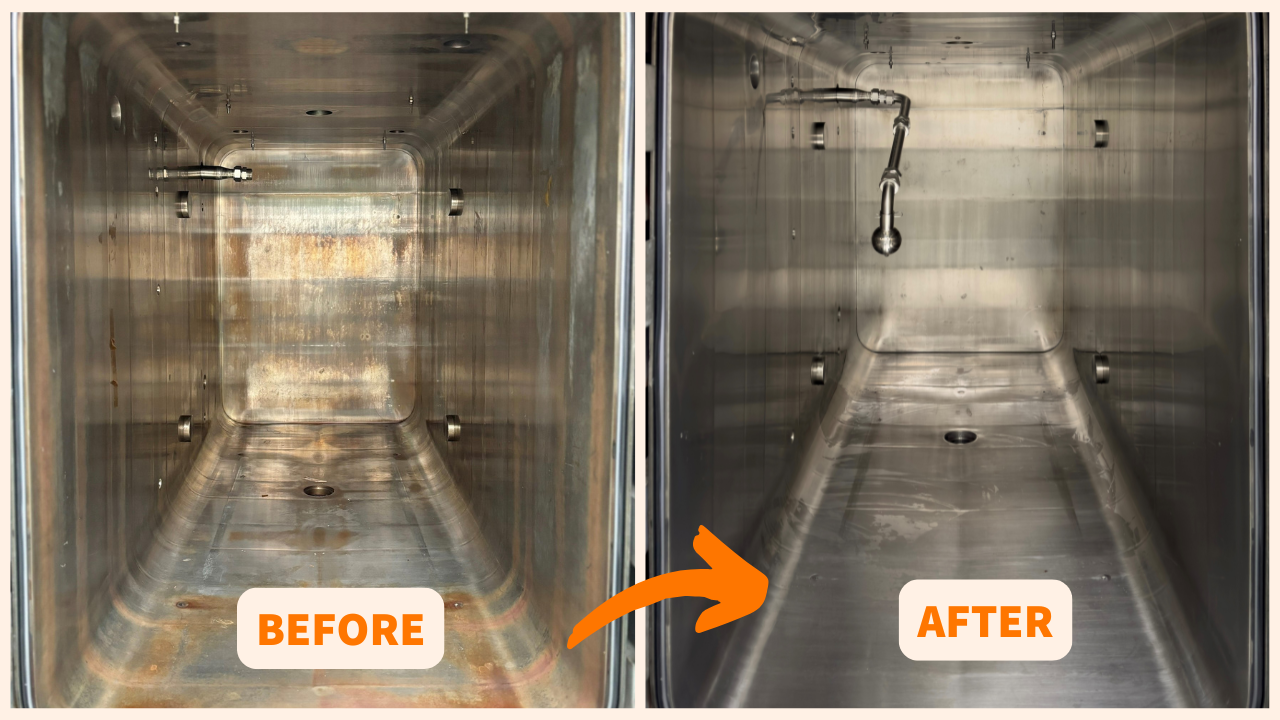

Derouging Your Steam Autoclave Machines

by Neil Brook on October 16, 2024

Rouge, a reddish-brown oxide film, is commonly classified into three types. This article specifically addresses the formation of rouge within steam autoclave machines and explores effective derouging methods to eliminate it.

Ensuring Pharmaceutical Equipment Longevity With Biofilm Removal

by Neil Brook on October 1, 2024

Sanitation is a paramount concern for equipment used in pharmaceutical manufacturing, with even low contamination levels putting products at risk of spoilage and endangering consumers.

4 Facts About The Passivation Procedure For Stainless Steel Pipes

by Neil Brook on September 24, 2024

Passivation is one of the primary treatment processes for stainless steel pipes. Passivation can improve durability, longevity, and resistance to corrosion.

General ASTM A967 Standards Requirements To Follow

by Neil Brook on September 3, 2024

Stainless steel may be highly durable and resistant to corrosion, but in many industries it still requires regular treatment, using methods such as passivation, to ensure its longevity and to protect equipment from deterioration. Passivation should rigidly adhere to ASTM A967 standard …

Tech Jargon You Need To Know To Understand Stainless Steel Passivation

by Neil Brook on August 6, 2024

Understanding the specialist language associated with stainless steel passivation is crucial for anyone involved in industries in which it is necessary to maintain equipment and hygiene. In this article, we’ll demystify the key terms and concepts involved in stainless steel passivatio …